Decrease counting thresholds for the greatest dilution plating in sequence have to be justified. Numbers of colonies on a plate Keep to the Poisson distribution, Therefore the variance on the necessarily mean worth equals the signify price of counts.

Manufacture of pharmaceutical h2o employs sequential device operations (processing steps) that deal with certain drinking water quality attributes and shield the Procedure of subsequent treatment method steps. A typical evaluation approach to pick an correct h2o excellent for a selected pharmaceutical goal is demonstrated in the decision tree in Determine two. This diagram may very well be utilised to assist in defining prerequisites for certain h2o employs and in the choice of unit functions. The ultimate unit Procedure employed to generate Drinking water for Injection is limited to distillation or other procedures equivalent or remarkable to distillation inside the removal of chemical impurities along with microorganisms as well as their elements. Distillation has a long history of responsible general performance and might be validated to be a device operation for the creation of Drinking water for Injection, but other systems or mixtures of systems is often validated as becoming equivalently helpful. Other systems, for example ultrafiltration subsequent other chemical purification process, could be suited inside the production of Water for Injection if they can be demonstrated as a result of validation for being as productive and dependable as distillation. The appearance of latest materials for more mature technologies, such as reverse osmosis and ultrafiltration, that let intermittent or steady Procedure at elevated, microbial temperatures, demonstrate promise for a valid use in making H2o for Injection.

Within this move, the whole quantity of aerobic organisms is determined, which is an important indicator to evaluate the hygienic quality of medicines.

Delivering A variety of sound oral dose enhancement and production solutions from three state-of-the-artwork services

USP moved faraway from these chemical attribute tests to up to date analytical technologies for the majority waters Purified Drinking water and Drinking water for Injection. The intent was to up grade the analytical systems without the need of tightening the standard requirements. The 2 modern day analytical technologies employed had been TOC and conductivity.

Test Detrimental Manage: Complete a unfavorable Regulate as test sample, utilizing the preferred pre incubated diluent in place of the test planning. There needs to be no progress of microorganisms. Failed negative Handle demands investigation.

For use as one of several bases for measuring the sanitation volume of the whole technique of drug generation

Inform AND ACTION Concentrations AND SPECIFICATIONS Though the use of alert and motion stages is most often connected with microbial knowledge, they are often related to any attribute. In pharmaceutical h2o units, almost every top quality attribute, in addition to microbial good quality, can be quite read more swiftly identified with around-real time success. These brief-hold off data can provide fast program general performance suggestions, serving as ongoing course of action Management indicators.

Factors and distribution strains needs to be sloped and fitted with drain points so the program is often completely drained. In chrome steel distribution devices wherever the drinking water is circulated in a large temperature, useless legs and reduced-flow situations should be prevented, and valved tie-in factors should have size-to-diameter ratios of six or much less. If created of heat tolerant plastic, this ratio need to be even a lot less in order to avoid awesome details wherever biofilm advancement could happen. In ambient temperature distribution units, unique care need to be exercised to avoid or limit dead leg ratios of any dimensions and provide for entire drainage.

To find out whether or not the drug is contaminated or its diploma of contamination, and Command the quality of drugs

Set up, Components OF Design, AND Element Collection Installation methods are very important because they can have an impact on the mechanical, corrosive, and sanitary integrity from the process. Valve installation Perspective must boost gravity drainage. Pipe supports ought to present correct slopes for drainage and should be made to guidance the piping sufficiently underneath worst-case thermal and movement problems. The methods of connecting procedure components which includes models of operation, tanks, and distribution piping require careful focus to preclude prospective difficulties. Stainless steel welds must present trusted joints which might be internally smooth and corrosion-cost-free. Low-carbon chrome steel, suitable wire filler, the place needed, inert fuel, computerized welding equipment, and standard inspection and documentation aid to guarantee suitable weld good quality.

In new water devices exactly where There is certainly incredibly limited or no historic facts from which to derive information traits, it really is common to simply create initial notify and motion stages determined by a mix of equipment layout abilities but beneath the method and product specifications exactly where drinking water is utilized. Additionally it is typical, specifically for ambient drinking water systems, to microbiologically “mature” over the first 12 months of use. By the end of this era, a relatively continuous condition microbial population (microorganism types and degrees) could have been allowed or promoted to acquire because of the collective consequences of regimen system servicing and operation, such as the frequency of unit Procedure rebeddings, backwashings, regenerations, and sanitizations.

So that you can isolate certain microbial contaminants, FDA laboratories, and several during the business, make use of some sort of enrichment media made up of inactivators, like Tween or lecithin. This is vital to inactivate preservatives usually current in these types of product or service and supplies a greater medium for harmed or slow developing cells.

A validation program to get a water process typically involves the following steps: (1) establishing criteria for top quality characteristics from the concluded water plus the source h2o; (2) defining suited unit functions and their functioning parameters for obtaining the desired completed h2o good quality attributes with the accessible supply h2o; (3) deciding upon piping, tools, controls, and checking systems; (4) establishing an IQ phase consisting of instrument calibrations, inspections to verify the drawings correctly depict the final configuration in the h2o method and, the place vital, Particular tests to confirm which the read more installation satisfies the look specifications; (5) establishing an OQ phase consisting of tests and inspections to validate that the tools, technique alerts, and controls are functioning reliably Which suitable inform and action degrees are founded (This phase of qualification could overlap with components of another step.

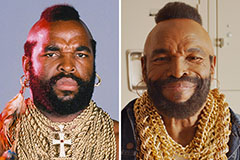

Mr. T Then & Now!

Mr. T Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Brian Bonsall Then & Now!

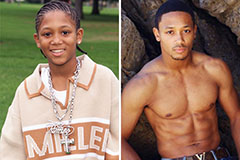

Brian Bonsall Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now!